Scaling and bolting or shotcrete ground conditions that create a hazard to persons shall be taken down or supported before other work or travel is permitted in the affected area.

How does roof bolting work.

However it is these applications and those in the next category that have been most troublesome for design.

Rotate chucks to turn bolts and open expansion heads against rock formations.

Resin and resin bolting information about resin and resin bolting.

Force bolts into holes using hydraulic mechanisms of self propelled bolting machines.

Perform ventilation tasks such as hanging ventilation curtains and tubes.

Installation can be done in a few easy steps.

General roof bolts have to work much harder in beam building than in suspension and higher densities of support are required.

Where the roof is extremely weak.

Dust rocks after bolting.

Install various types of bolts including truss glue and resin bolts traversing entire ceiling spans.

Roof bolting is hard work where miners often have to lift cumbersome pieces of heavy metal into awkward positions.

We asked some mining roof bolters a few questions to find out what else does their work day look like.

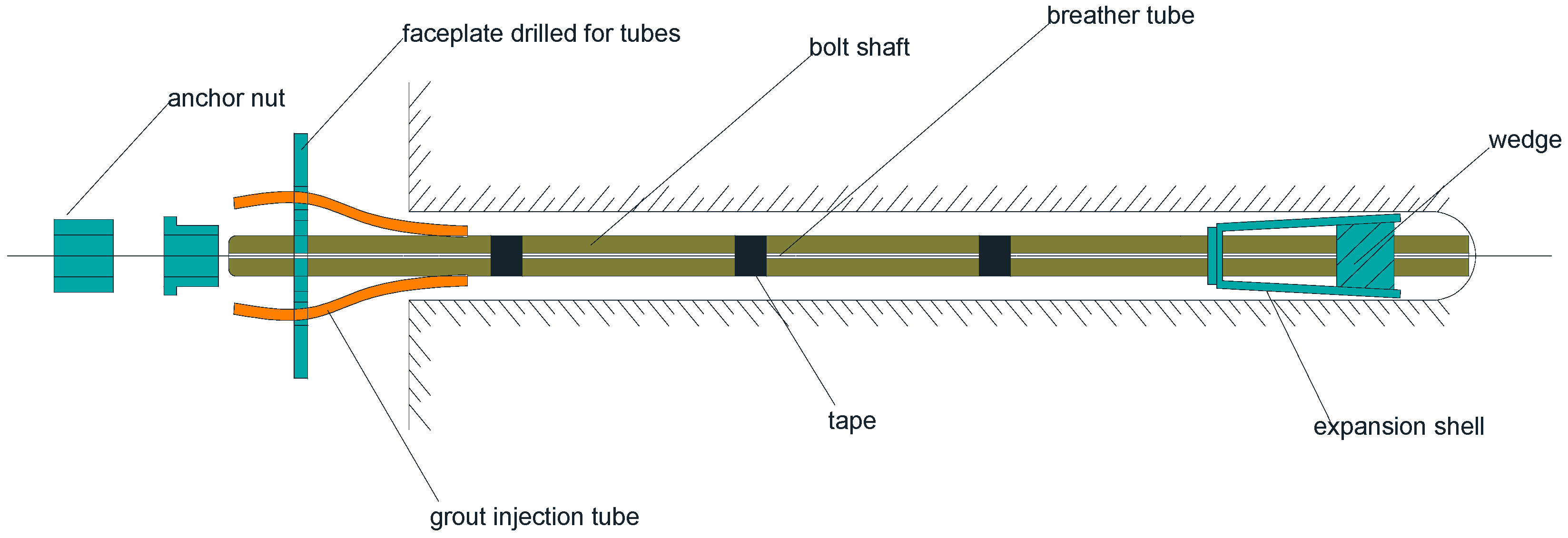

Explores the installation of roof bolts.

Force bolts into holes using hydraulic mechanisms of self propelled bolting machines.

High roof conditions can present a problem for people who usually work with low profile machines and vice versa.

Here is what we found.

When conditions change and the miners are out of their element safety can become a concern.

.jpg)