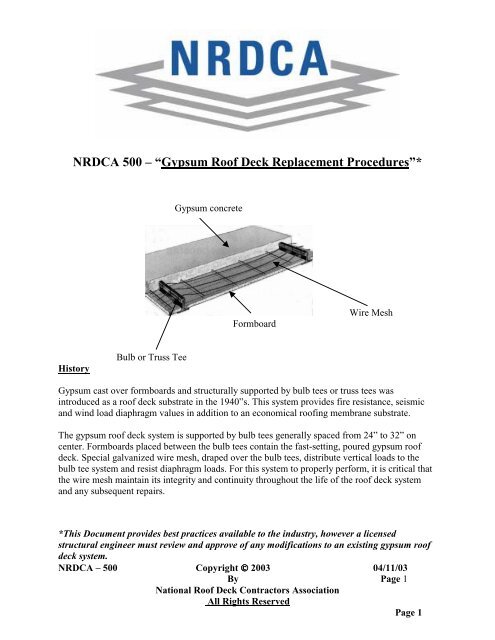

Keydeck mesh is made up of 2 hexagonal mesh composed of woven 19 gauge galvanized wires with an additional 16 gauge galvanized longitudinal wire placed at every 3 interval of its width.

History of gypsum roof deck.

Picture story of gypsum roof materials required 1.

These include office complexes schools public buildings shopping malls and warehouses located throughout the united states.

Bags of gypsum concrete 3.

It was not until 2 years later in 1945 that we knew the 2 500 000 sq.

Conclusion 4 1 when operating on thin flimsy roofs members should always be aware of the.

Therefore many poured gypsum roof decks were not designed and installed with diaphragm shear strength in mind.

Venting lwic installed over structural concrete and other non venting substrates.

Using the roof deck as a structural diaphragm was a california development and worked its way across the nation in the late 1950 s and early 60 s.

In the 1950 s new construction methods came in the way of new types of roof decking and dead level roof systems.

Galvanized wire mesh removing deteriorated gypsum deck 4.

1946 a new name.

Of poured roof deck in oak ridge tennessee was for the manhattan project.

Upon this observation members shall make immediate notification to the incident commander and proceed to evacuate the roof.

Metal roof decking and gypsum roof decks were more prevalent and required a roof insulation overlay.

Keydeck woven wire mesh is commonly used in repair of poured gypsum roof decks.

Only gravity load and wind uplift loads were considered.

Bulb tees are high strength lightweight steel sections.

Deteriorated gypsum deck deck repair sequence 2.

3 4 the presence of a gypsum roof deck will be indicated by a white powdery residue during saw operations.

Cutting section from deck.

This was a cost effective way of construction back then and today.